CT6601

Related products

Product display

video introduction

product feature

THE BEST QUALITY

EFFICIENT FLUSHING

CLEAN WIT THOUT DEAD CORNER

High efficiency flushing

system, whirlpool strong

flushing, take everything

away without dead corner

Remove cover plate

Quickly remove cover plate

Easy installation

easy disassembly

and convenient design

Slow descent design

Slow lowering of cover plate

The cover plate is

slowly lowered and

damped to calm down

OUR BUSINESS

The mainly export countries

The product export to all of the world

Europe, USA, Middle-East

Korea, Africa, Australia

product process

FAQ

1. What's the production capacity of production line?

1800 sets for toilet and basins per day.

2. What is your terms of payment?

T/T 30% as deposit,and 70% before delivery.

We will show you the photos of the products and packages before you pay the balance.

3. What package/packing do you provide?

We accept OEM for our customer, the package can be designed for customers' willing.

Strong 5 layers carton filled with foam, standard export packing for shipping requirement.

4. Do you provide OEM or ODM service?

Yes,we can do OEM with your own logo design printed on the product or carton.

For ODM,our requirement is 200 pcs per month per model.

5. What are your terms for being your sole agent or distributor?

We would require a minimum order quantity for 3*40HQ - 5*40HQ containers per month.

We often say this toilet bowl is good and this toilet is bad. So why are toilets divided into good and bad ones, and what are the differences in their production processes?bathroom accessories

The difference in raw materials is very critical in determining the quality of a product.

If the raw materials used are not good, no matter how good the later process is, the quality of the product cannot be guaranteed. The materials used in good toilets are generally made of a mixture of high-quality quartz stone and kaolin. It not only makes the product stronger but also has the advantages of fire resistance, water resistance, corrosion resistance, etc., and the product has a longer service life.

Mix and stir

These raw materials are sent directly to the hopper for mixing and uniform mixing, and then enter the grinder through the conveyor belt.

After grinding carefully, add water and stir to form a slurry

Slurry mixed with silica sand

High-pressure grouting varies from factory to factory

A good toilet factory high-pressure grouting uses a high-pressure grouting machine, which can increase the working pressure to more than 4500psi (300kg/cm2) within 3-6 seconds. The liquid water-stop agent can be effectively poured into 0.1mm fine cracks during construction. The efficiency is more than three times faster than traditional technology, and the waterproof and leak-proof effect is more durable and effective.

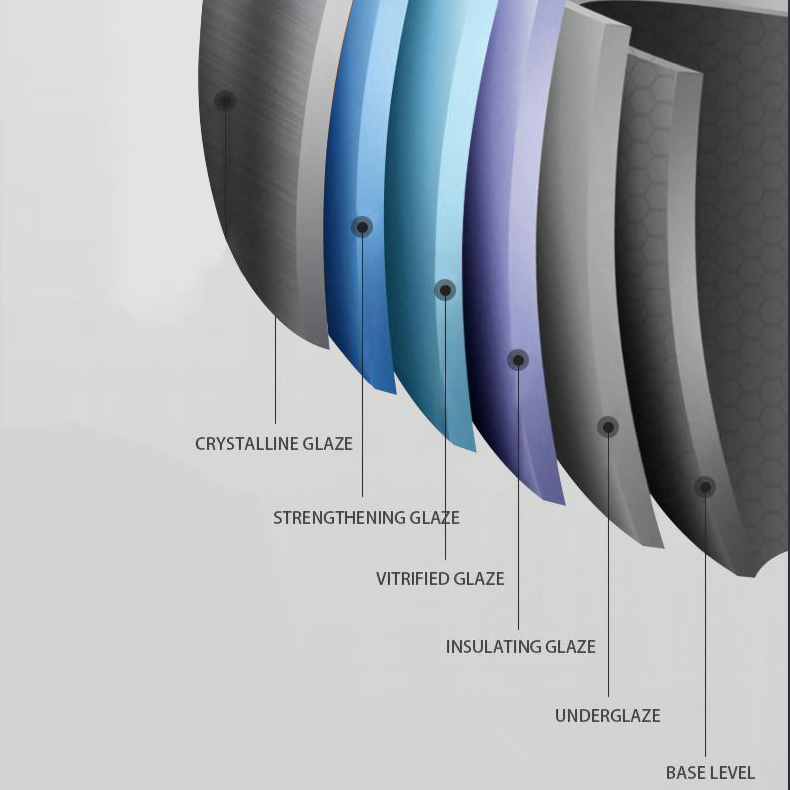

Glazing varies from factory to factory

Glazing is a very important step in the toilet manufacturing process. The glazing layer itself has the functions of preventing water seepage, easy cleaning, sterilization, and anti-pollution. At the same time, the glazing layer also has certain radioactive properties. Long-term use is very harmful to the human body. A good toilet factory has two original radiation protection technologies: first, it uses high-crystalline nano self-cleaning glaze to enhance self-cleaning while effectively reducing radiation; second, it uses a special small-diameter spray gun during the glazing process to make the glazing layer lighter and more uniform. Impermeable while reducing radiation from the source.

The glaze is different. The glaze of a good product is not only waterproof but also easy to take care of. It has a higher safety factor and does not cause radiation. It is more environmentally friendly as a household item.

High temperature kilns vary from factory to factory

At present, in the entire sanitary ware industry, high-temperature kilns are roughly divided into two types: the first one is: the traditional high-temperature kiln that relies on manual control accounts for more than 80% of the industry. The temperature in the kiln is only about 1000°C, and the temperature difference in the kiln is large, which makes it difficult to produce products. The quality is unstable. The second type is: imported computer-controlled high-temperature kiln, the temperature in the kiln is as high as 1260℃, the temperature difference at any point in the kiln is less than 5℃, the cost is high, and the quality of the produced products is stable.

Differences in firing quality In addition to the craftsmanship and raw materials, what determines the quality of the toilet is its firing. The products on the market now are divided into two types: manual firing and CNC firing. Due to the large temperature difference in manual firing, the quality of products in different batches is different. The computer-controlled firing temperature is relatively constant, so the hardness of the fired products is of high quality and there will be no problem of incomplete firing.

Factory inspection

Each toilet undergoes machine inspection and manual inspection. Strictly inspect the size, specifications, and flushing strength.

The first test: vacuum side leakage; high-pressure gas detection to see if there are bubbles or pores in the whole unit.

The second test: test the water, check the flushing area, flushing strength, whether the glaze is smooth, and whether the water parts pass the test. Apply colored oil-based paint to the inner wall of the toilet for two hours, then rinse with water to test the self-cleaning properties of the self-cleaning glaze and the strength of flushing.

Inspection Gap Whether we buy main materials or furniture, they must be inspected by the manufacturer before leaving the factory.

Good manufacturers often have strong self-inspections and can strictly control the quality of each product, so that it is more secure for later use.

Process: mud pairing, stirring - mold grouting - preliminary blank repair - drying in the oven - blank repair - water supply - blank inspection - glaze spray - scraping and pedicure - climbing the kiln - kiln Furnace firing - unloading porcelain - appearance inspection - repair - functional test - packaging - entering the warehouse,

After repeated testing of 72 processes, such a toilet was completed.